Description

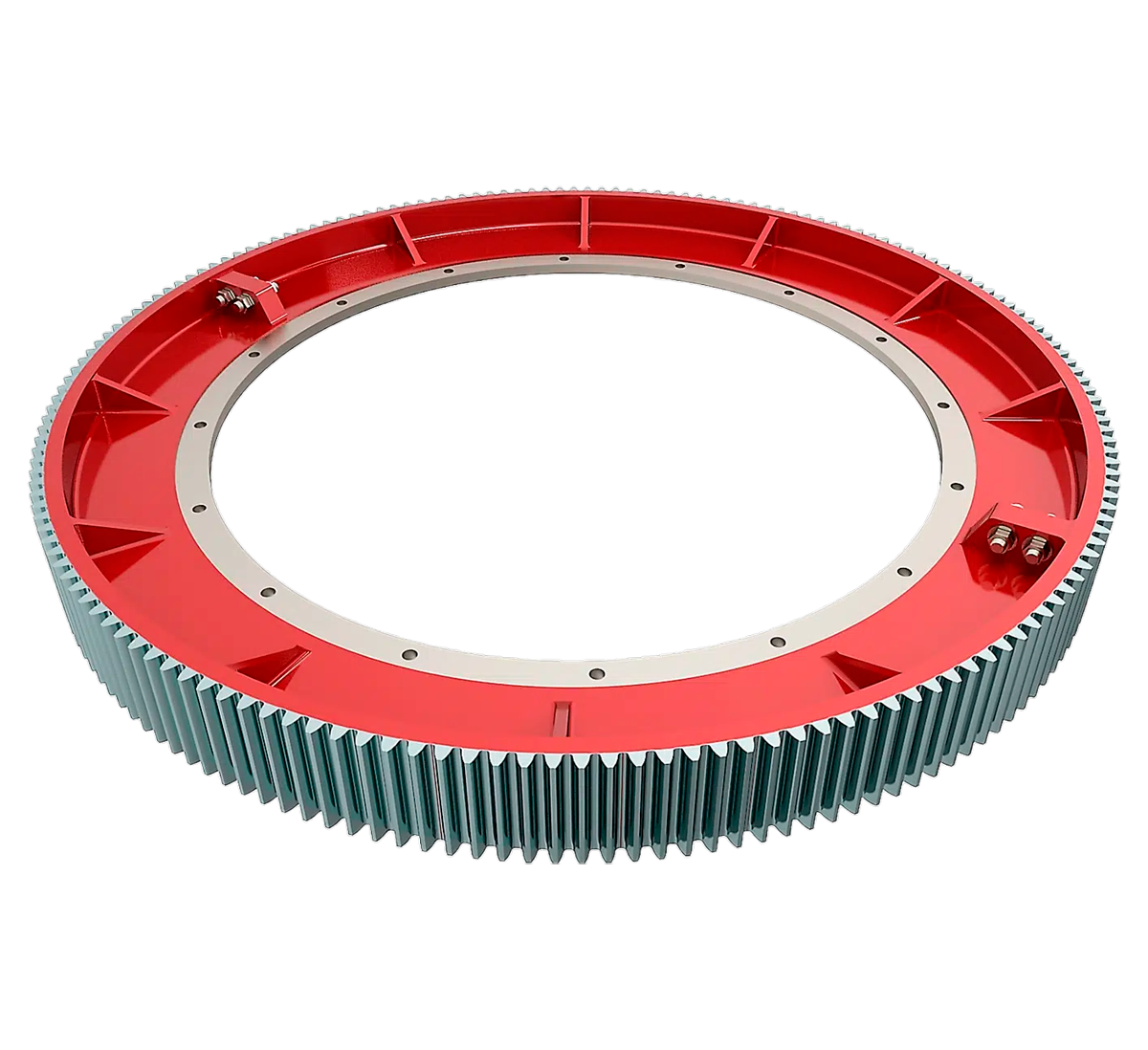

A GIRTH GEAR, or gear ring, is a large circular gear designed to transmit torque between the main drive shaft and the driven shaft of heavy machinery. Typically mounted around the outer circumference, often on the underside, girth gears are essential components in large rotating equipment. These gears are commonly found in rotary kilns, dryers, and ball mills, where their robust design ensures reliable operation under demanding conditions.

Girth gears are critical in industries such as mining, cement, and mineral processing, where maximizing uptime is crucial. Whether in the production of copper, gold, platinum, or iron ore, these gears provide the durability and precision needed to keep operations running smoothly and efficiently.

- High Torque Capacity: Engineered to transmit large amounts of torque between the main drive shaft and the driven shaft, ideal for heavy machinery.

- Robust and Durable Design: Manufactured with high-strength materials to ensure a long lifespan and reliable performance under demanding conditions.

- Circumferential Mounting: Installed around the circumference of the machinery, optimizing space and enhancing operational stability.

- Precision Gear Teeth: Designed for precise engagement, minimizing vibrations and wear, ensuring smooth and efficient operation.

- Easy Maintenance: The design allows for simplified maintenance, reducing downtime and operational costs.

- Rotary Kilns: Used in the cement and lime industries, where reliable torque transmission is critical for continuous operation.

- Rotary Dryers: Essential for industrial drying processes in sectors such as mining and chemical processing.

- Ball Mills: Commonly used in mining and mineral processing for grinding and crushing, where high torque and reliability are paramount.

- Mining Industry: Applied in the extraction and processing of metals such as copper, gold, silver, platinum, and iron ore, ensuring consistent performance in tough environments.

- Cement Industry: Utilized in large rotating machinery, contributing to the efficient production of cement and other construction materials.

- Mineral Processing: Used in the processing of minerals where uptime is critical, providing durable and reliable operation under high loads.