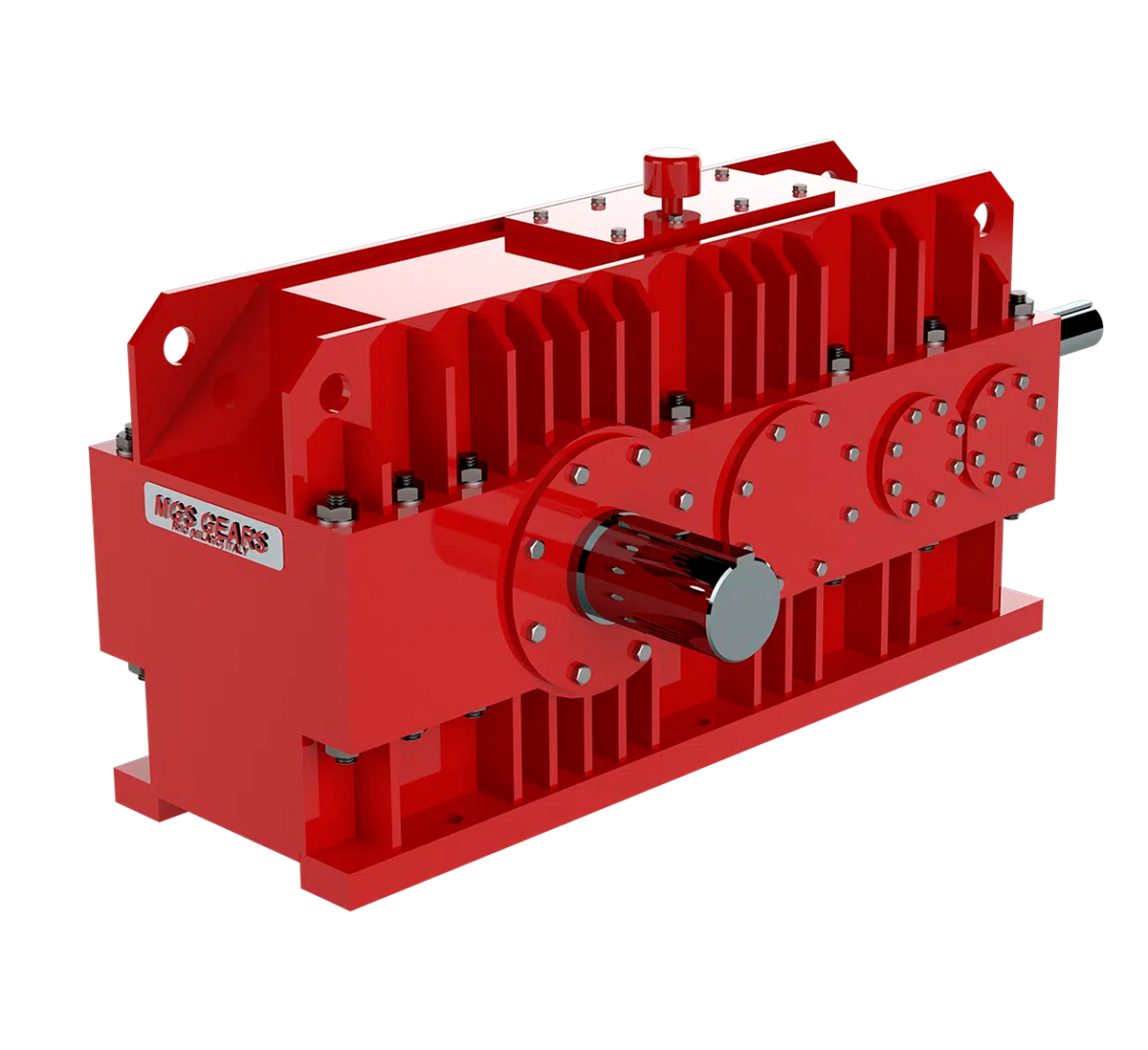

Description

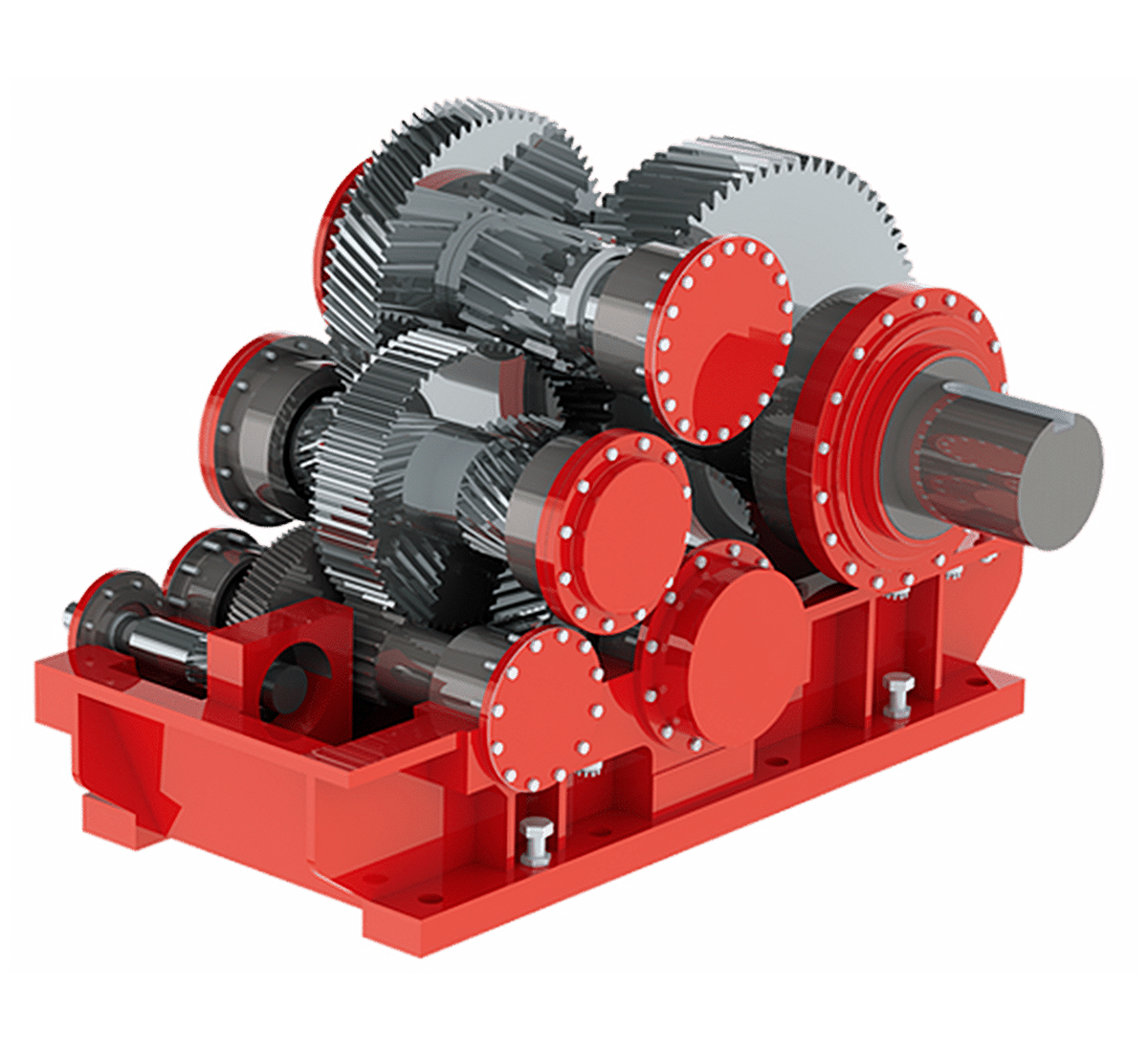

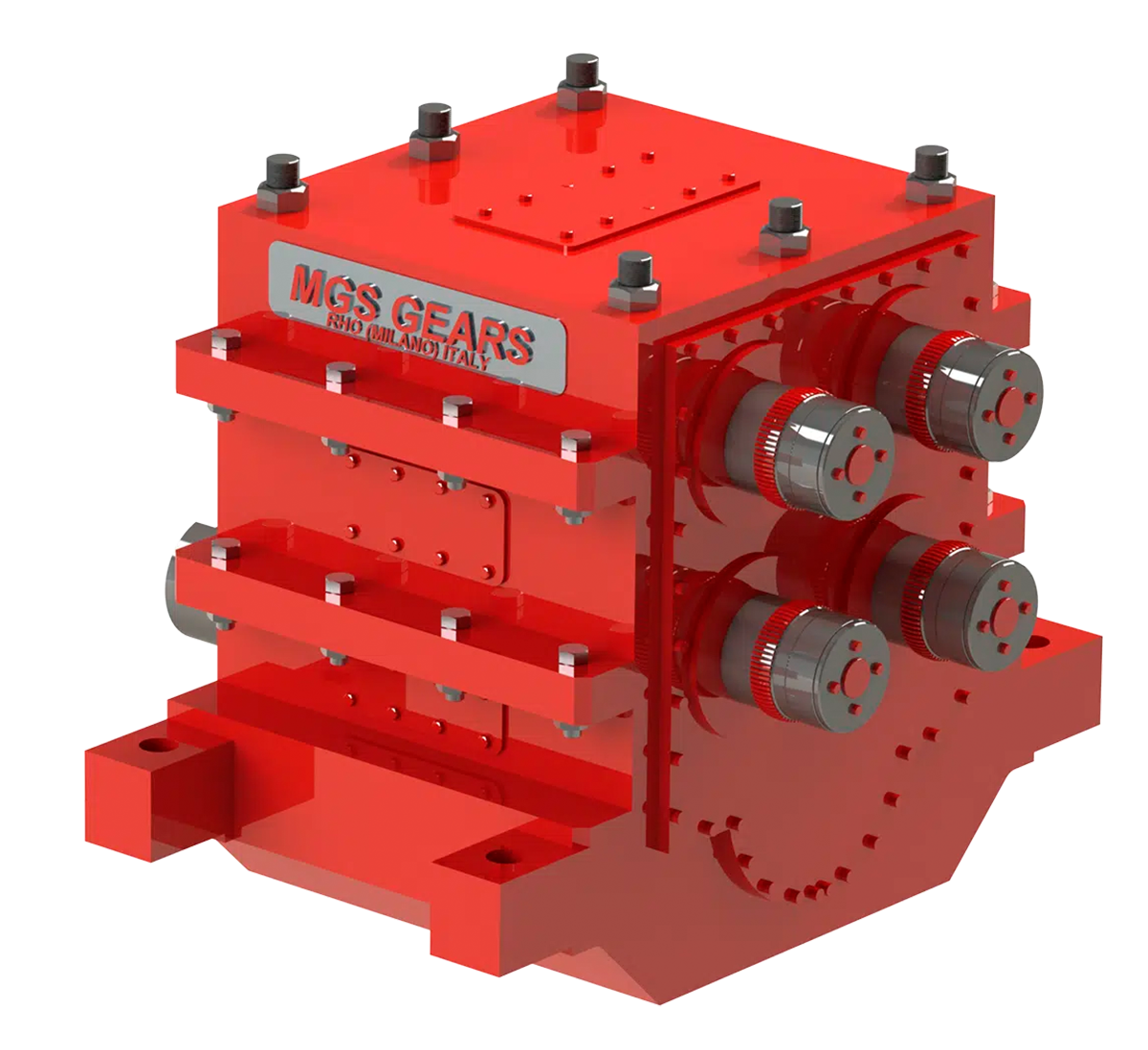

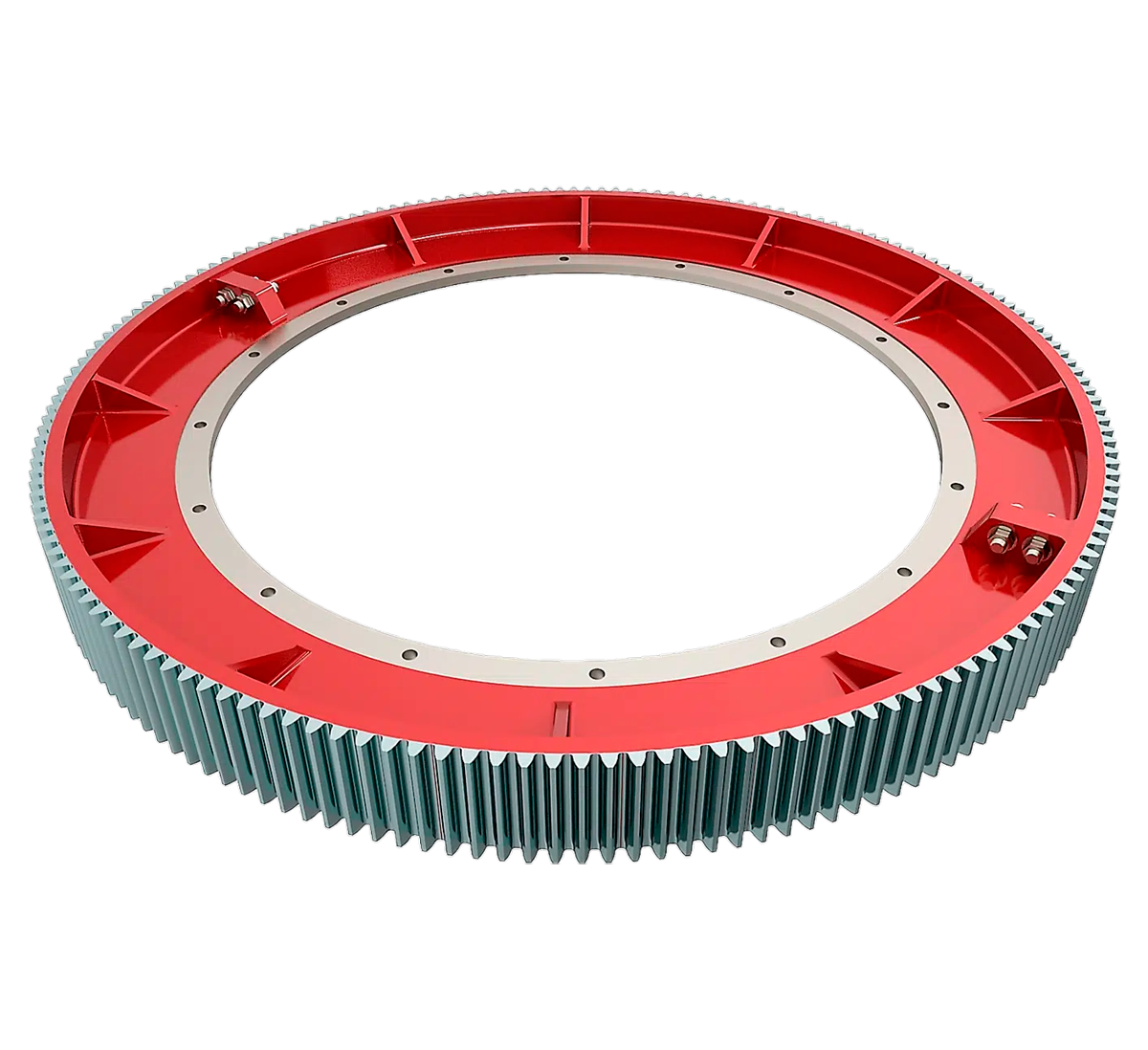

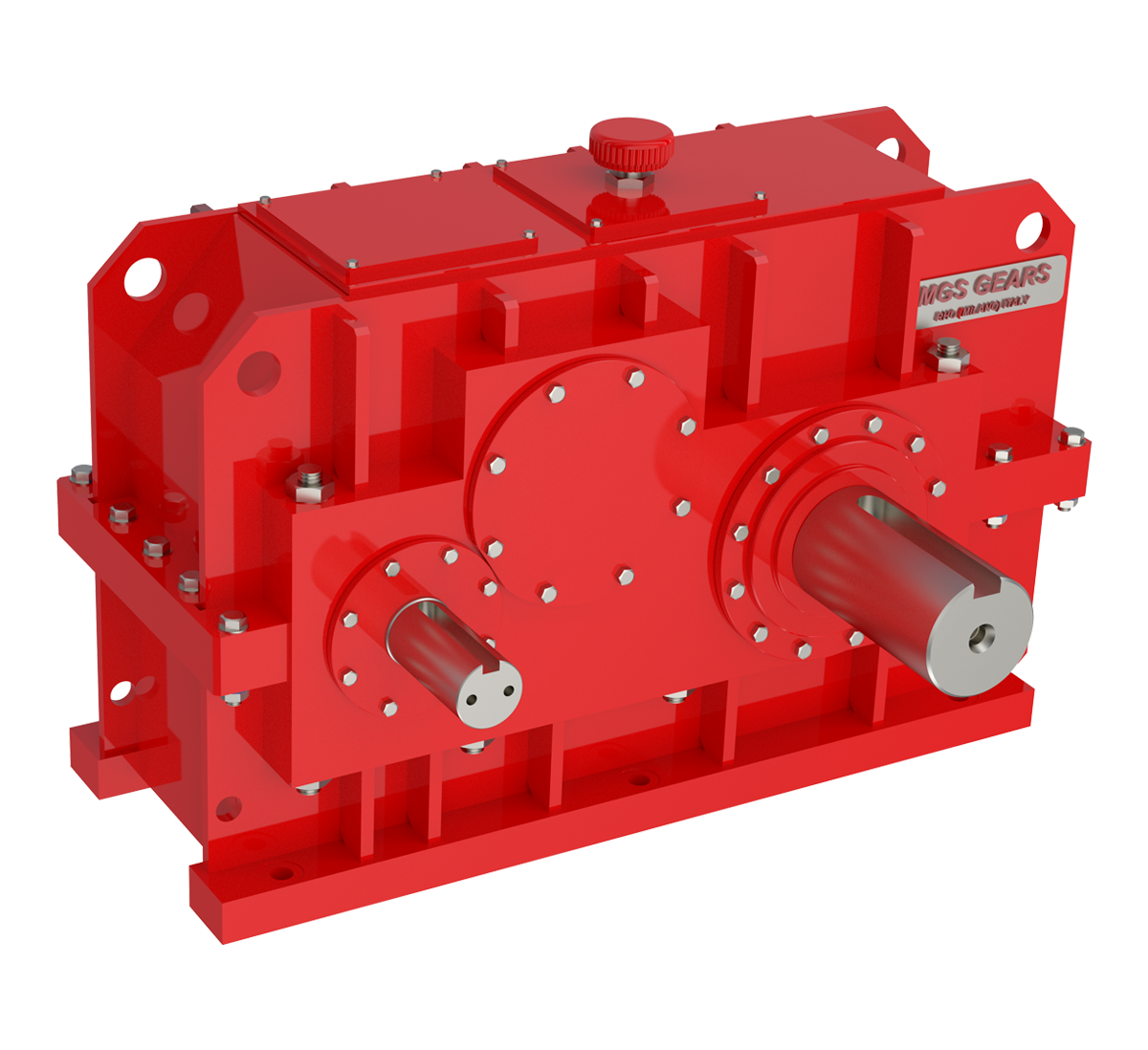

SPECIAL SPLIT TORQUE GEARBOX solutions from MGS Gears are designed to distribute torque across multiple paths, enhancing load distribution and enabling higher torque transmission without increasing the size or weight of the gearbox. This innovative design uses multiple gear trains, ensuring that the load is split evenly across the gears, which significantly reduces the stress on individual components and enhances the overall durability of the system.

The split torque design not only allows for the handling of higher loads but also improves efficiency and reliability in demanding applications. By distributing the force, these gearboxes maintain compact dimensions, offering a space-saving solution for industries requiring high-performance torque transmission. Their robust construction, combined with the ability to handle high torques, makes them ideal for heavy-duty applications across various sectors.

- Torque Distribution: Splits torque across multiple paths, reducing the load on individual gear sets and increasing overall efficiency.

- High Torque Capacity: Designed to handle significantly higher torque without increasing the gearbox size, making it ideal for force-intensive applications.

- Compact and Efficient Design: Offers a space-saving solution while maintaining high performance, ideal for environments with space constraints.

- Enhanced Durability: Distributing the load across multiple gear trains reduces component stress, leading to longer service life and higher reliability.

- Reduced Wear and Tear: By balancing the load, the gearbox experiences less wear, resulting in lower maintenance needs and reduced downtime.

- Customizable Configurations: Can be tailored to meet specific industry and application needs, ensuring maximum flexibility.

- Optimized Power Transmission: Ensures smooth and efficient power transfer, even under extreme loads or continuous operation.

- Mining: Used in heavy-duty mining equipment such as excavators, conveyors, and crushers, where high torque and reliability are essential.

- Cement and Steel Plants: Ideal for large kilns, rolling mills, and presses that require continuous high-torque operation and efficient load handling.

- Sugar Industry: Used in sugar mills and centrifuges, providing efficient torque distribution for heavy-duty crushing and processing operations.

- Wind Energy: Applied in wind turbines, where split torque technology helps manage the high loads and torque involved in energy generation.

- Marine and Offshore: Employed in ship propulsion systems and other marine applications, offering reliable high-torque performance in a compact design.

- Power Generation: Utilized in turbines and other energy-generating systems where reliable and efficient torque transmission is critical.

- Automotive and Heavy Machinery: Suitable for large-scale machinery and vehicles requiring robust torque management, such as in construction and industrial settings.