Description

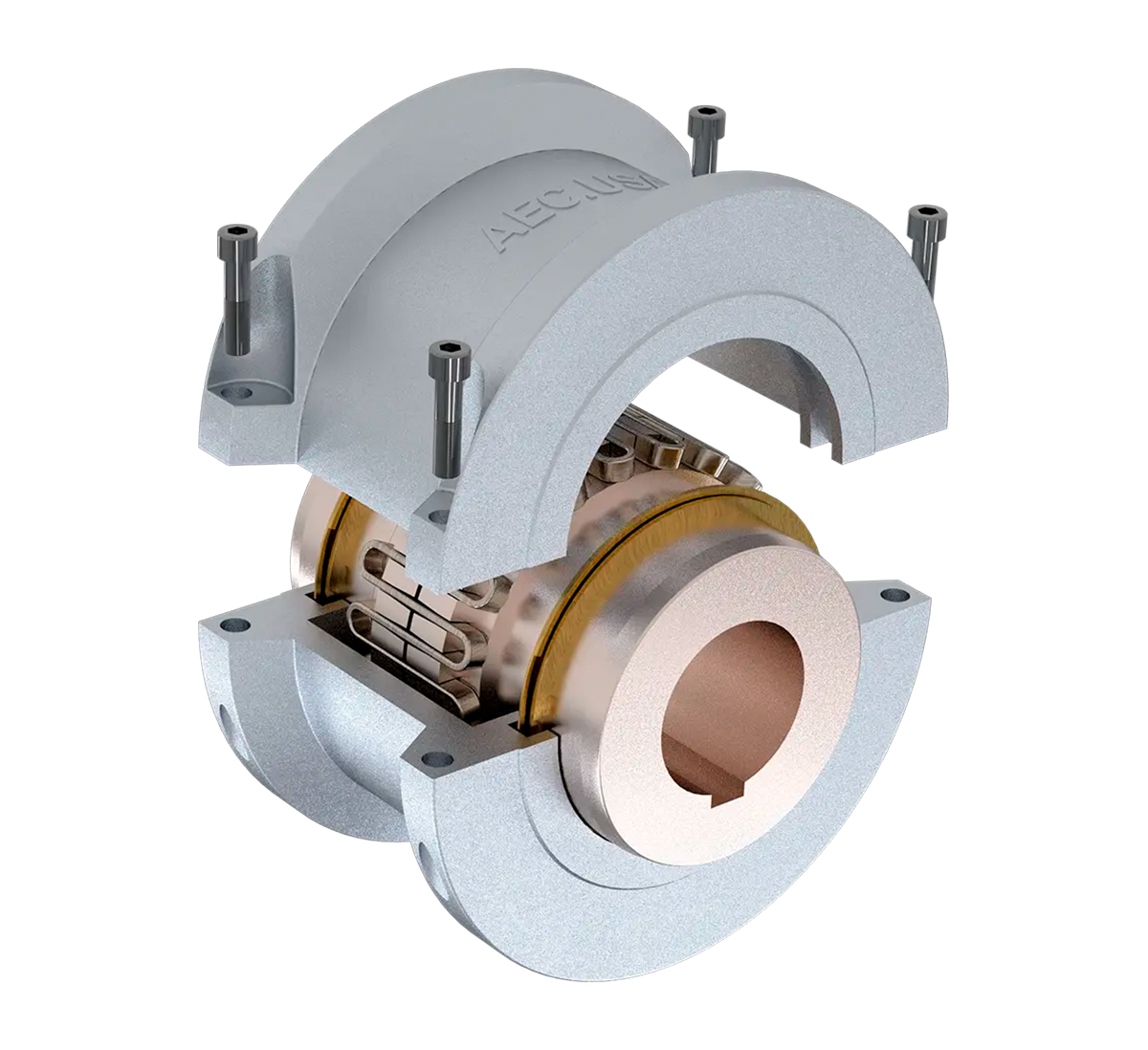

GRID COUPLINGS efficiently connect drive and driven shafts, offering excellent torque transmission while absorbing vibration and shock loads. Despite their compact size, they provide powerful protection for machinery by accommodating parallel and angular misalignment. When overloads or operational errors occur, grid couplings act as a safety device, preventing damage to shafts or related equipment. This makes them ideal for machines requiring both normal and reverse rotations in demanding environments.

Our Grid Couplings are engineered for durability and reduced maintenance, providing quick and simple installation. They ensure reliable operation in systems that frequently experience overloads or require smooth startup processes.

- Torque Control: Efficiently transmits torque, even in compact setups, making it suitable for high-demand applications.

- Vibration and Shock Absorption: Effectively reduces vibration and absorbs shock loads, extending the life of connected machinery.

- Safety Mechanism: Acts as a fail-safe, preventing equipment damage during overloads or misalignments.

- Handles Misalignment: Accommodates parallel and angular misalignment, ensuring smooth power transmission in complex systems.

- Low Maintenance: Designed for long-lasting durability with fewer inspections and repairs required.

- Easy Installation: Quick and simple assembly, reducing downtime during maintenance or setup.

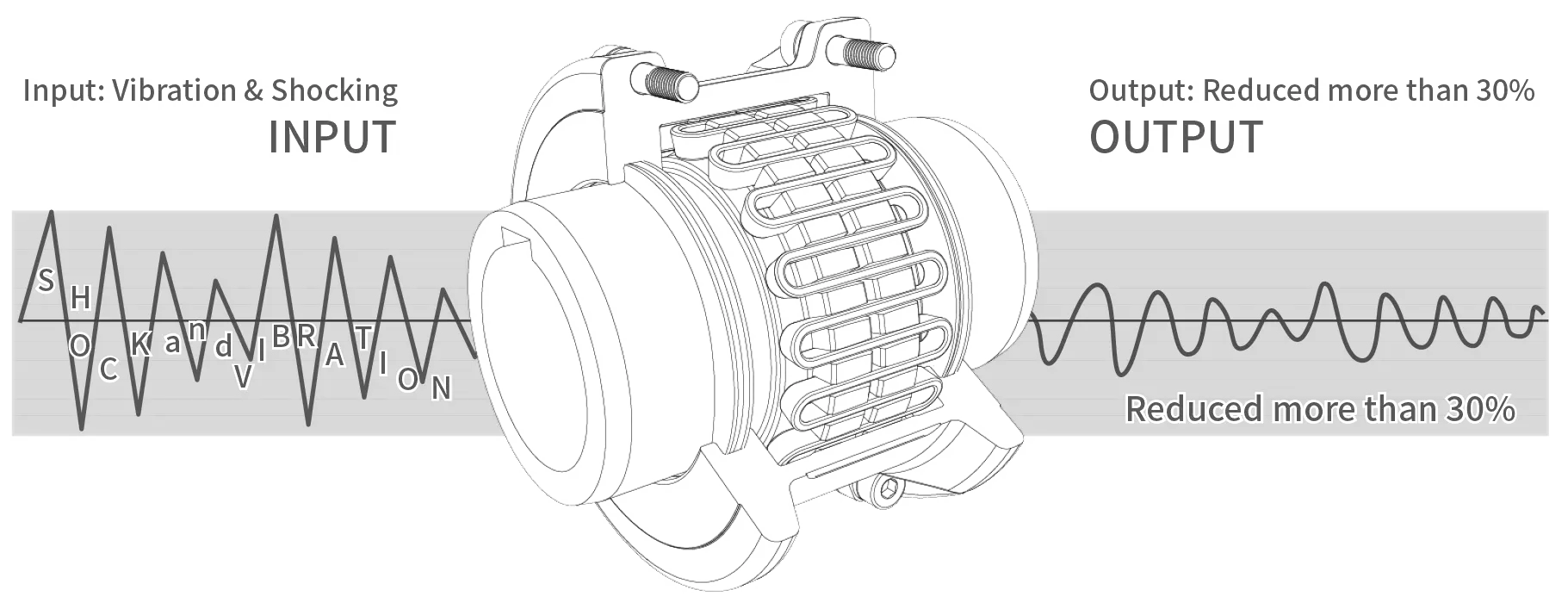

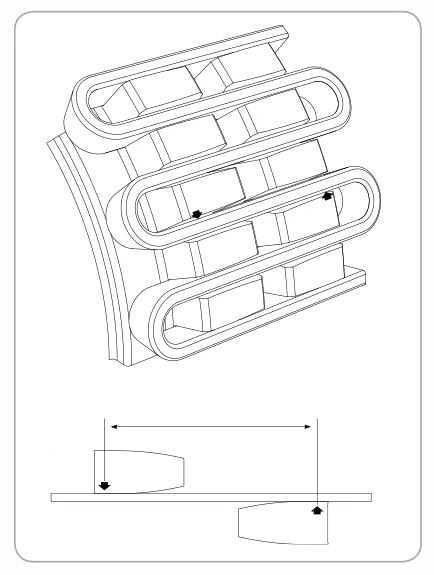

The absorption of mechanical vibration of Taper Grid coupling

Condition of Grid under light load

The vibrations and shocks are absorbed due to the curved surface of the teeth surface and the elasticity of the Grid when the Grid is operated with a straight line by receiving force from the outer surface of the teeth of the Hub.

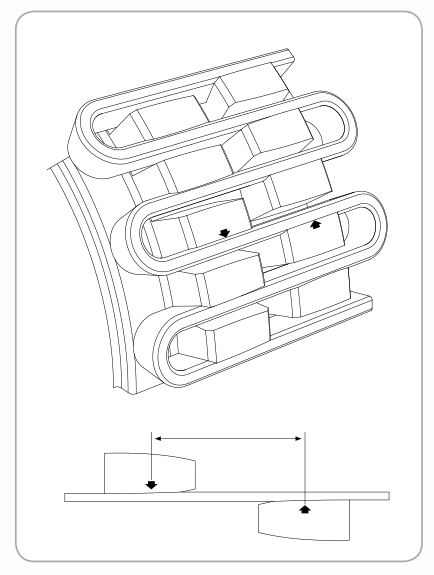

Condition of Grid under normal load

When the load occurs, the part where the power is concentrated moves to the center of the teeth of the Hub and absorbs the shock load with the elasticity from the bending Grid.

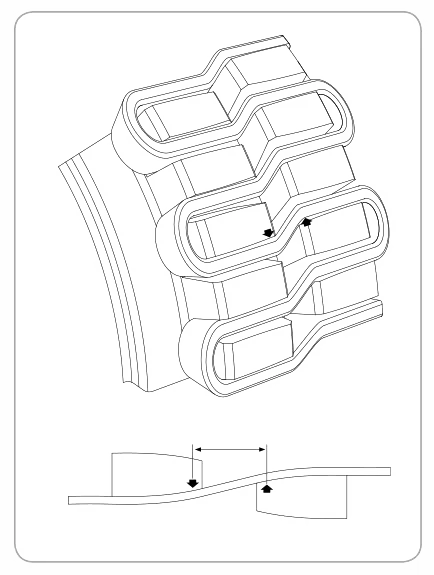

Condition of Grid under shock load at start

Due to transient overload, the part where the power is concentrated moves to the innermost section of the teeth of the Hub, and it smoothly absorbs severe shock within the range of torsional elasticity of Grid.

- Machinery with Vibration Sensitivity: Ideal for machines that must prevent transmission of vibration and shock loading, such as compressors or pumps.

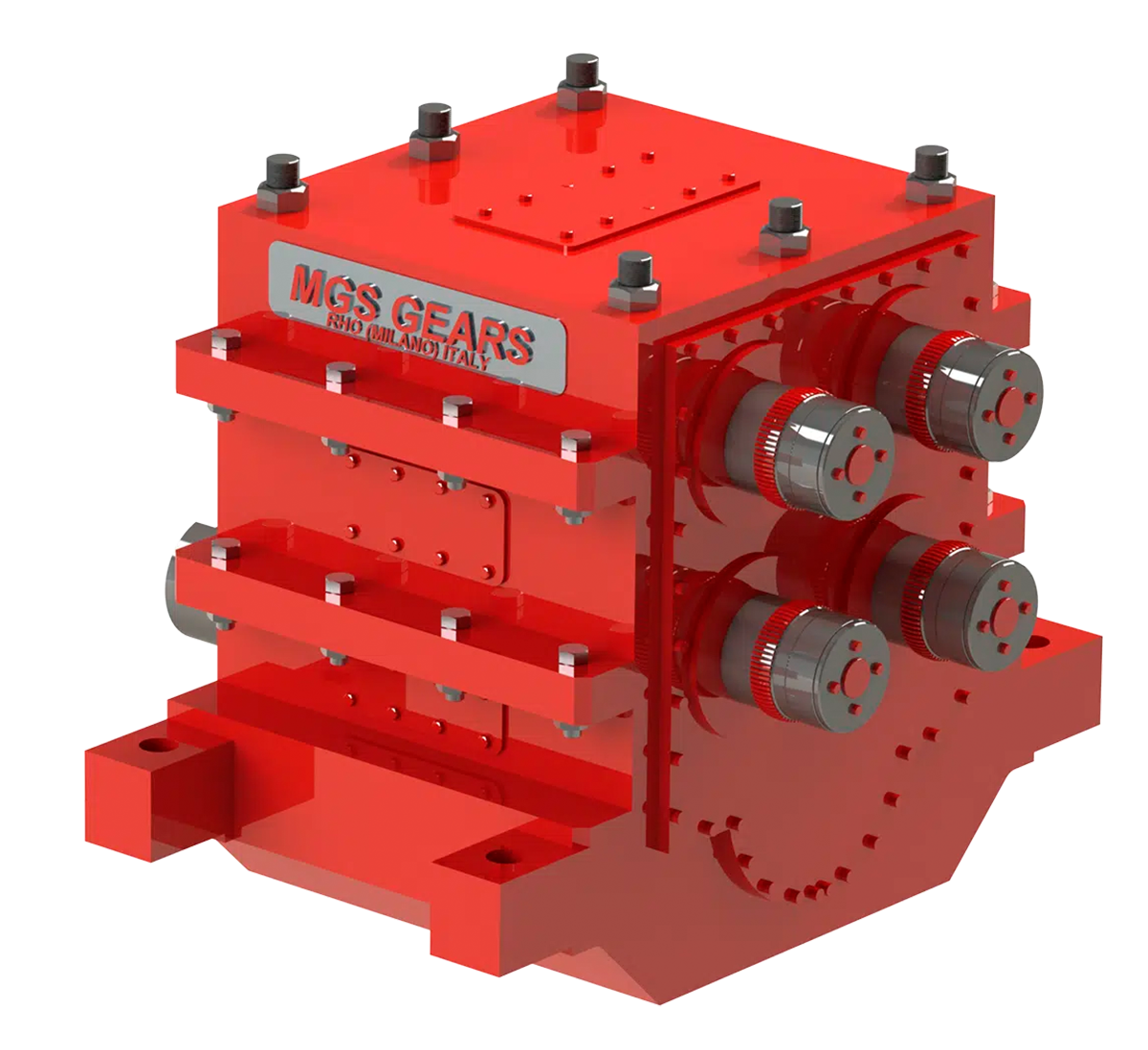

- Overload Protection: Common in systems where overload occurs periodically, such as in steel mills or mining operations.

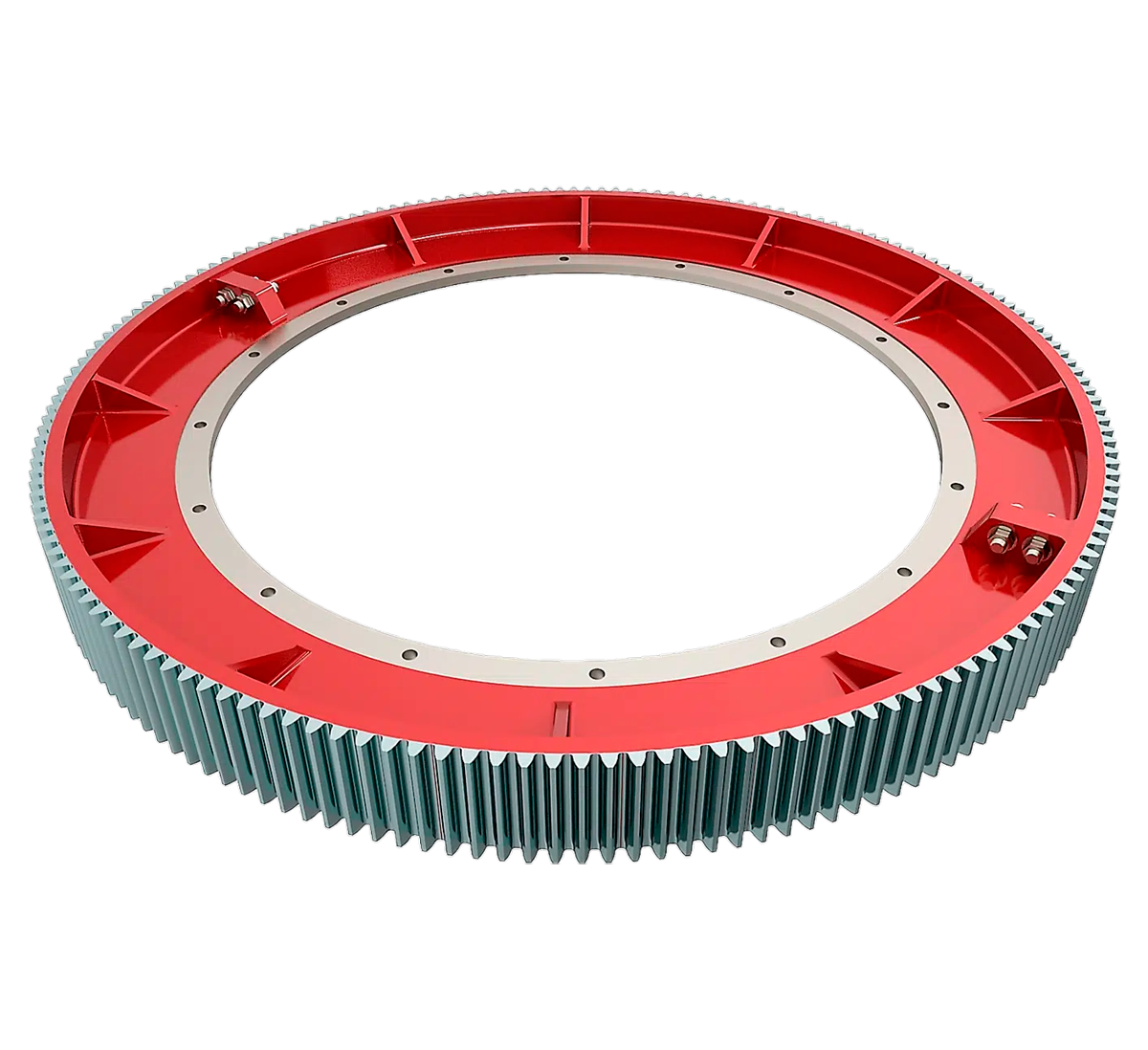

- Power Transmission with Misalignment: Used in applications requiring flexibility to accommodate misalignments, like conveyor systems.

- Normal and Reverse Rotation Systems: Suited for machines that require both forward and reverse operations, like in cranes or hoisting equipment.

- Heavy-Duty Industrial Equipment: Applicable in industries such as cement, mining, and power generation, where reliability and safety are critical.