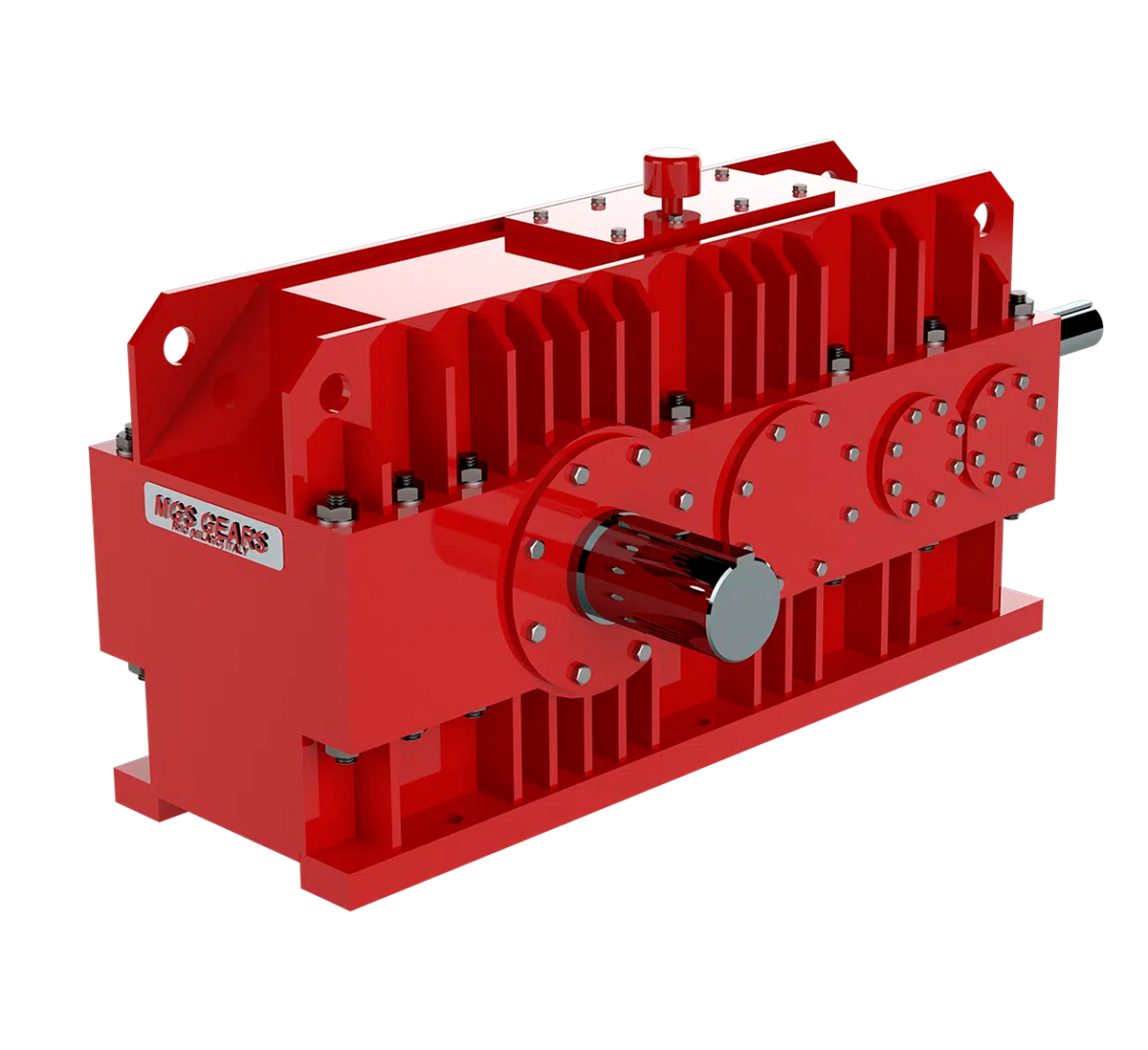

Description

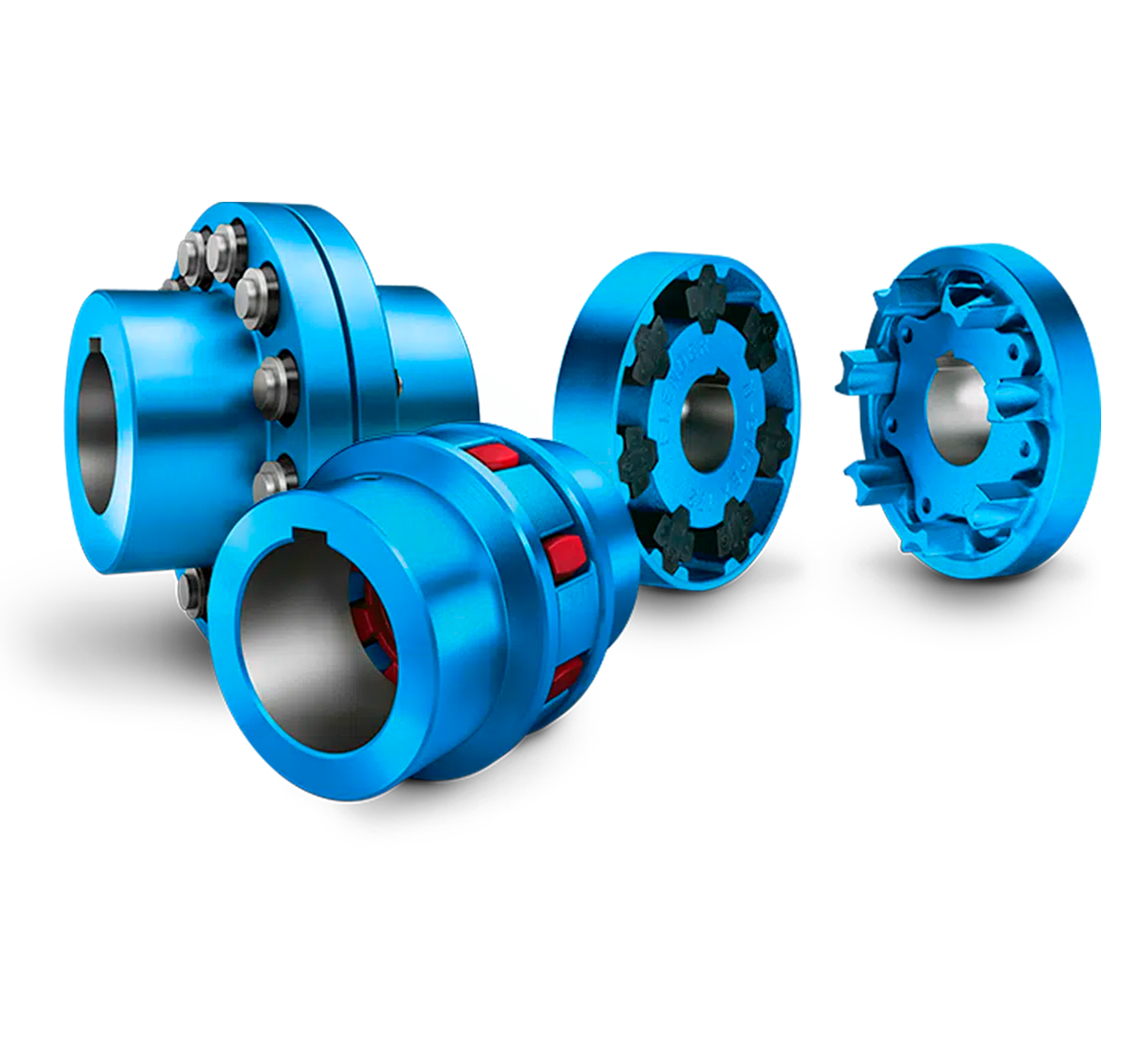

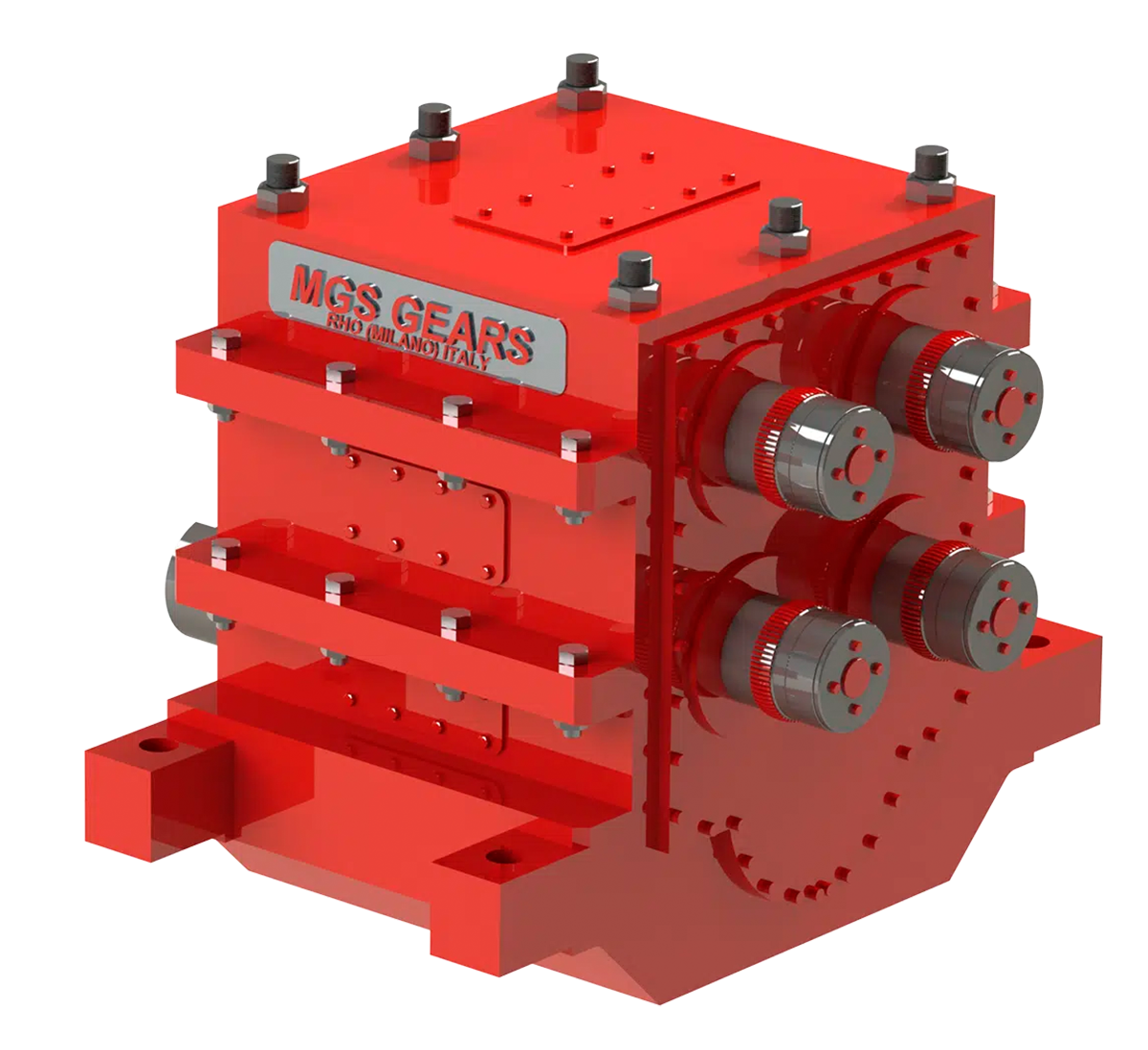

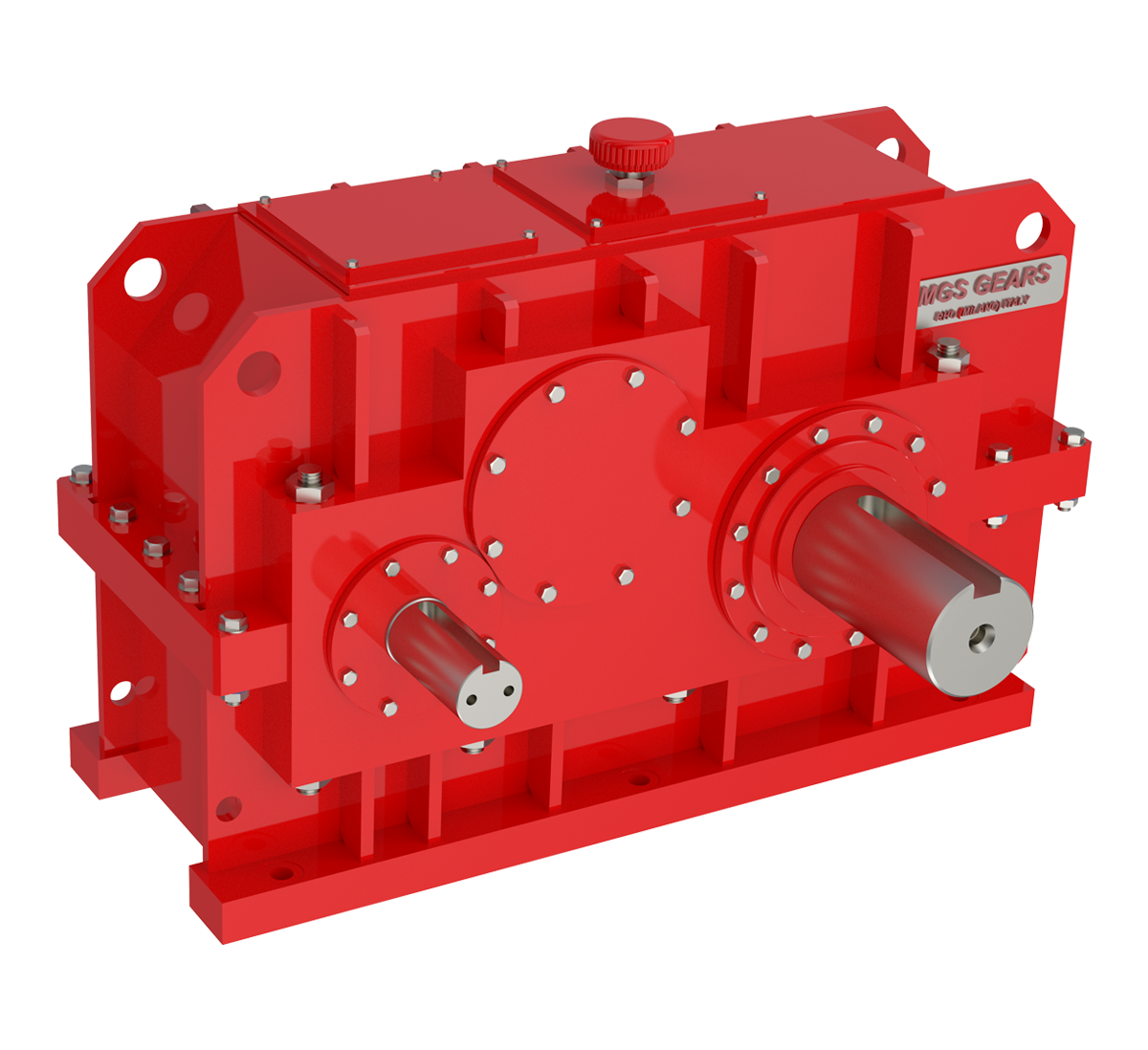

ELASTIC COUPLINGS are engineered to absorb torsional shocks and vibrations while correcting misalignments caused by factors such as vibrations or thermal expansions in the angular and parallel connections of rotating machinery shafts. These couplings ensure the smooth transmission of required power, preventing breakage and enhancing operational reliability. The Elastic Couplings supplied by MGS Gears are not only highly effective but also designed for easy assembly and coupling, making installation straightforward and maintenance simple.

- Absorbs Shocks and Vibrations: Effectively dampens torsional shocks and vibrations, protecting machinery from damage.

- Corrects Misalignments: Compensates for angular and parallel misalignments, ensuring smooth operation despite external factors like thermal expansion.

- Reliable Power Transmission: Guarantees consistent power transmission, preventing breakage and ensuring long-term durability.

- Easy Assembly: Designed for quick and simple installation, saving time and reducing maintenance efforts.

- Flexible and Durable: The elastic material provides flexibility and resilience under various operational conditions.

How do choose an Elastic Coupling?

MGS Gears designs, manufactures, and supplies a wide range of elastic couplings depending on your application. To correctly choose an elastic coupling, the following factors must be considered. Get in touch with us and we will help you select the best option!

- Type of machine

- Power of the machine

- Temperature conditions

- Load conditions and types (peaks, impacts, moments of inertia)

- Maximum noise level

- Speed of rotation of coupling

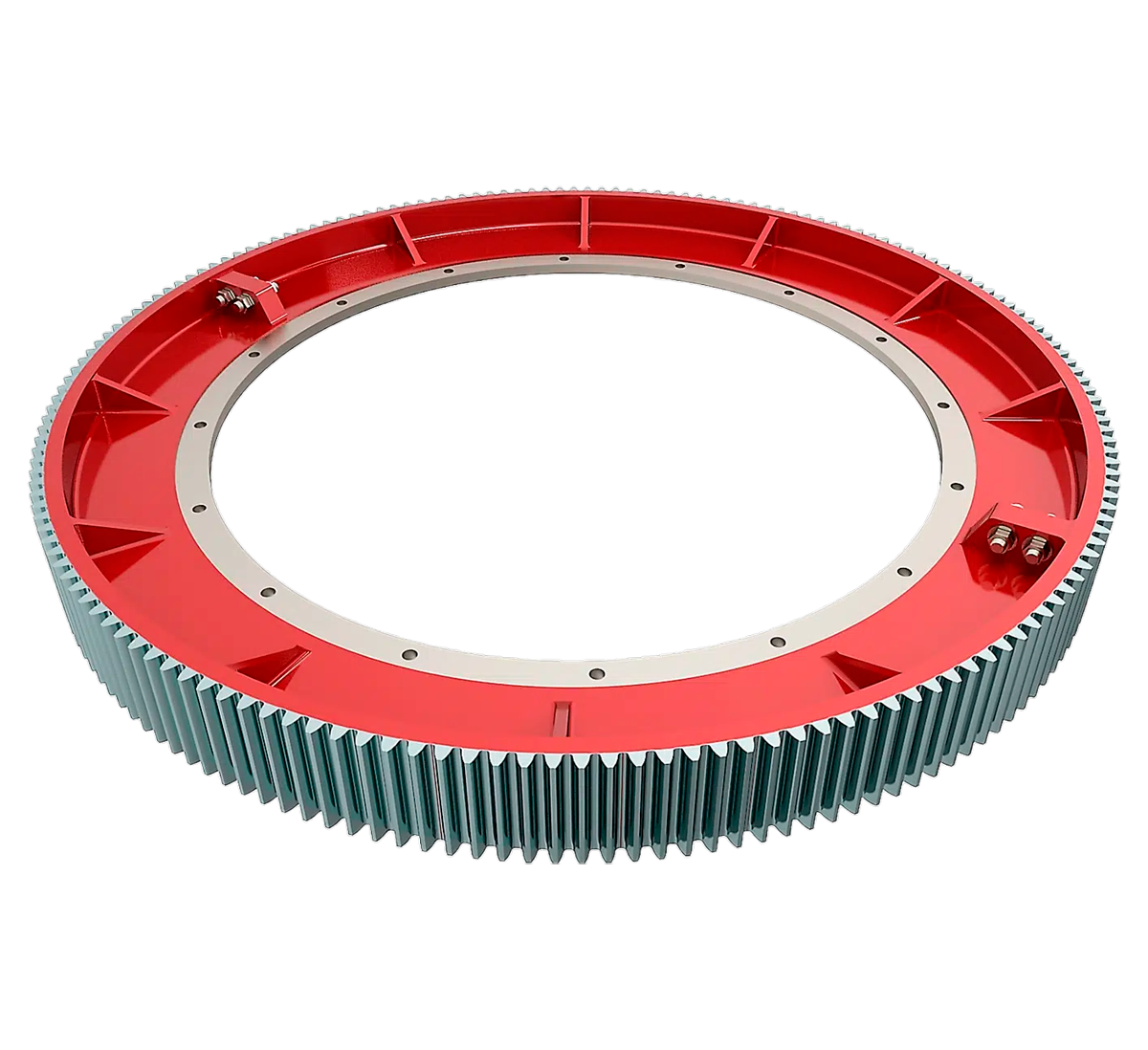

Elastic couplings are commonly used in a wide range of industrial applications, such as pumps, compressors, fans, and conveyors. They are also used in many types of power transmission systems, including gearboxes, and are often used in situations where precise alignment of the shafts is difficult or impossible to achieve. They are known for their ability to reduce vibration, noise and to dampen the shock loads. Elastic couplings are relatively low-cost, easy to install and maintain, and can be adjusted in the field to accommodate changes in the alignment of the connected shafts.

- Rotating Machinery: Ideal for machines requiring precise power transmission while compensating for vibrations and misalignments.

- Pumps and Compressors: Applied in systems that require reliable coupling solutions to manage operational stresses and vibrations.

- Material Handling Equipment: Used in conveyors and lifting systems, where smooth torque transmission and flexibility are essential.

- Automotive and Manufacturing: Suitable for production lines that need to handle frequent start-stop operations with minimal wear.

- Energy and Power Plants: Applied in turbines and other rotating systems where power transmission reliability is critical to maintaining operational efficiency.