Description

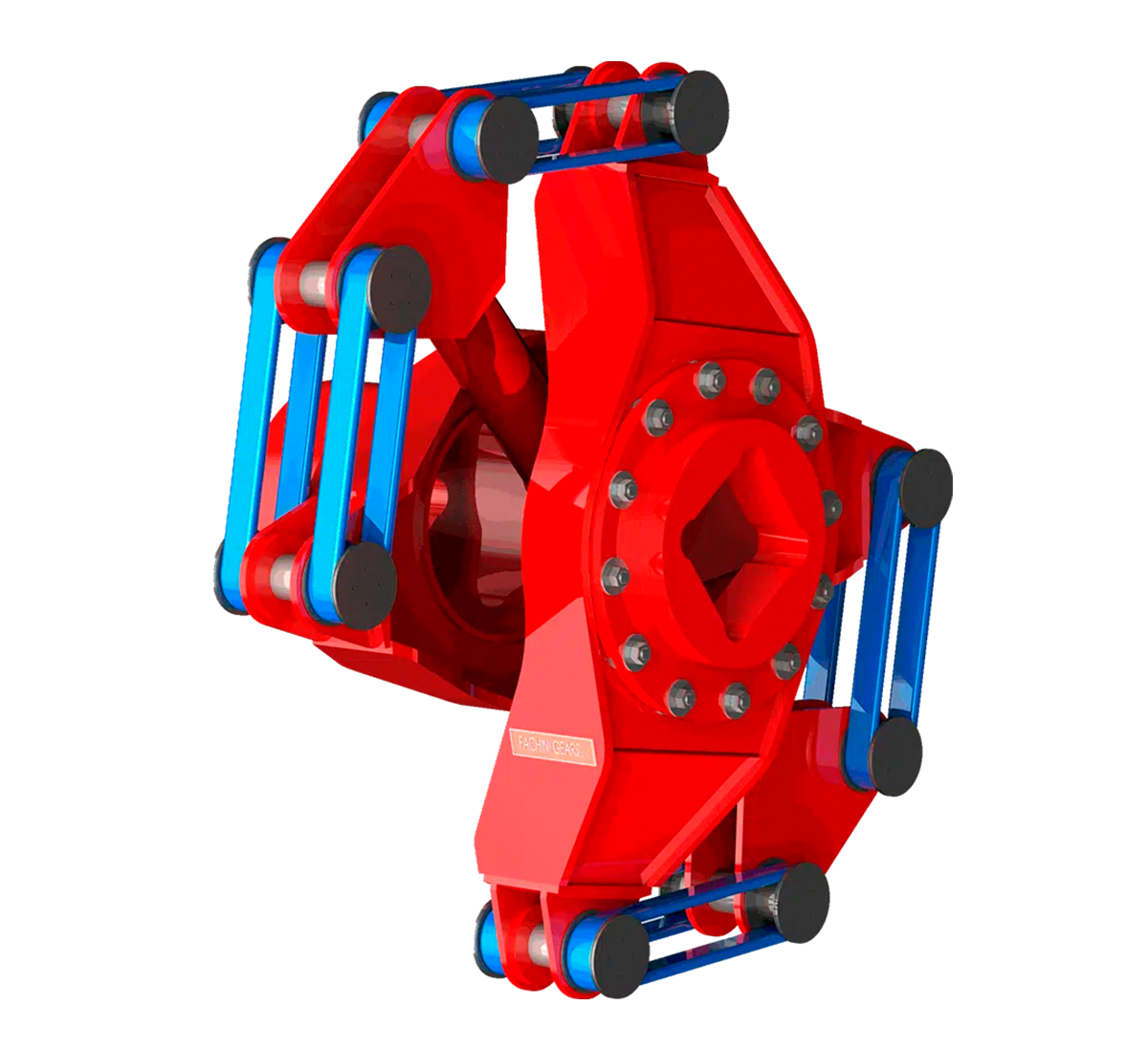

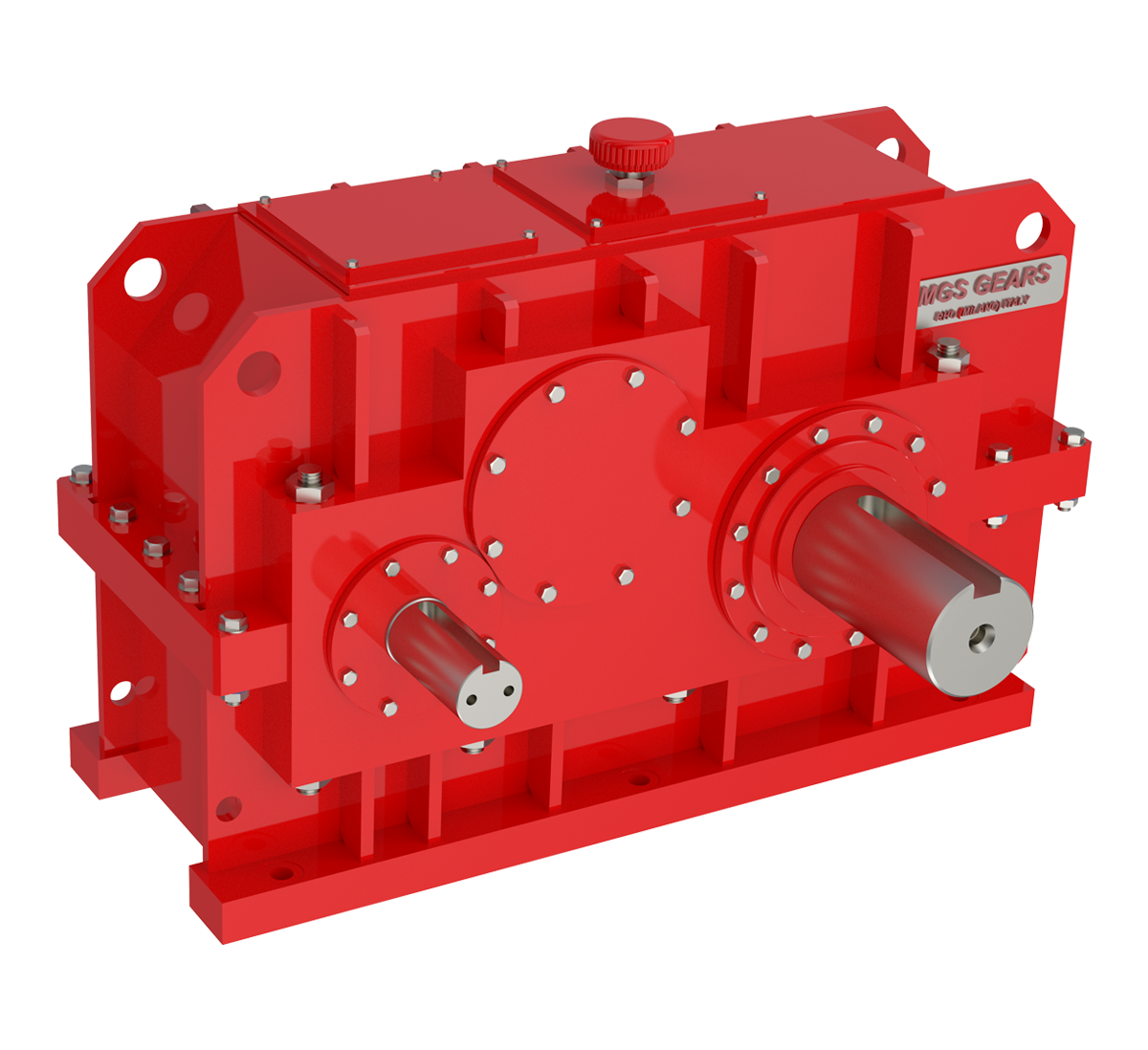

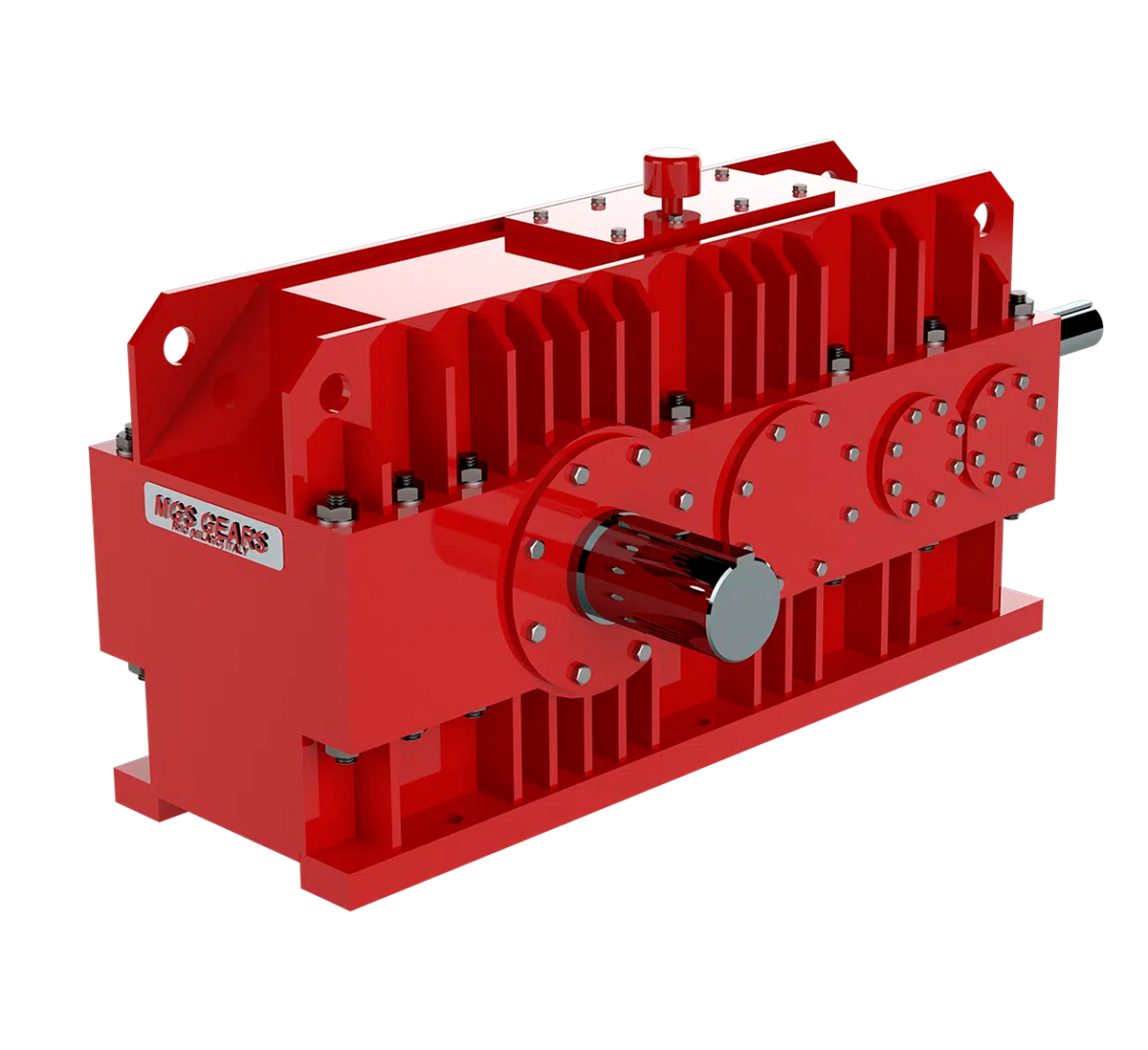

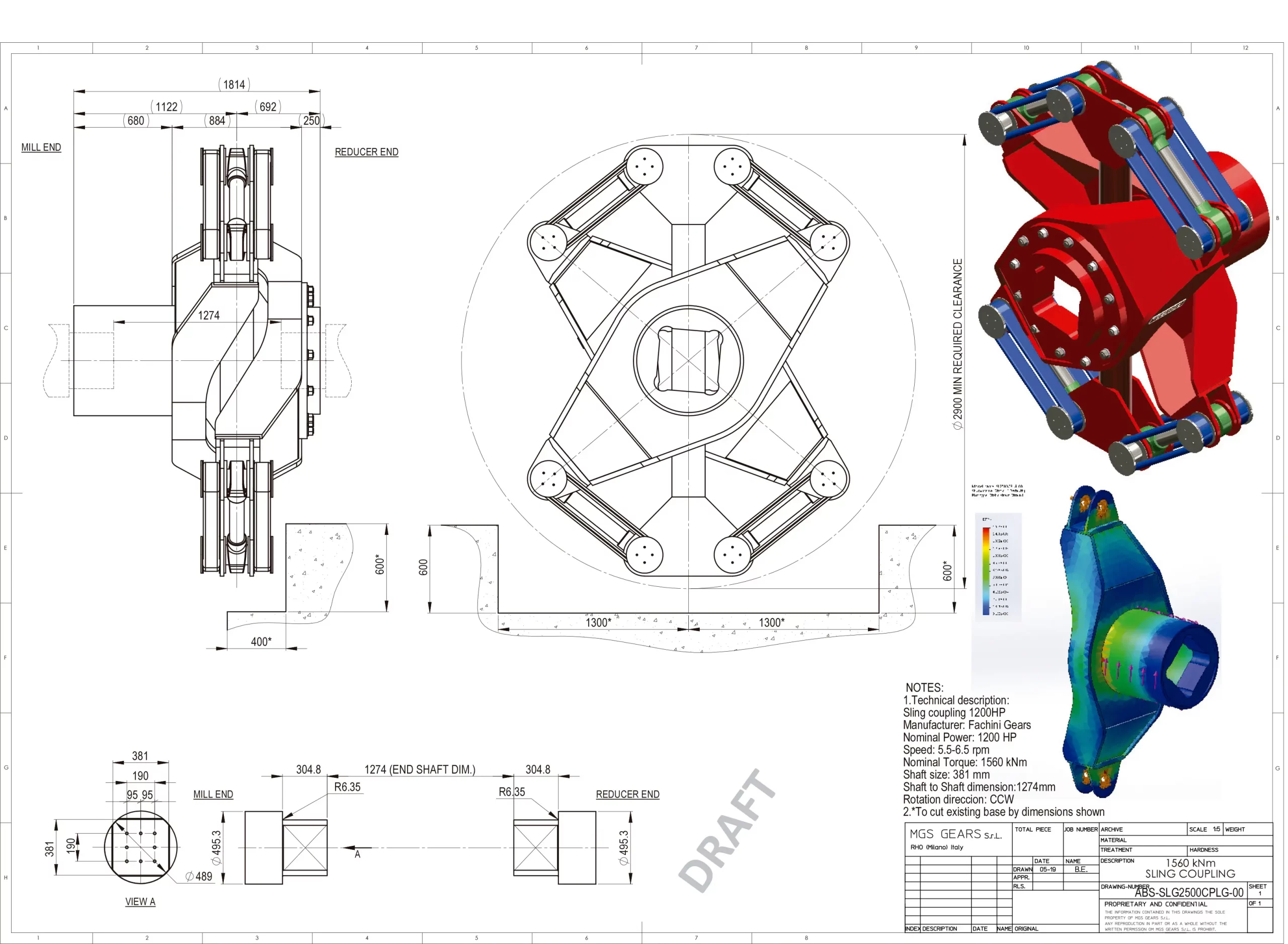

The Multi-Alignment SLING COUPLING is a revolutionary solution for transmitting torque from the gear to the mill top, designed to replace traditional square couplings and tail bars. Comprising a driving and driven half, the Sling Coupling directly connects the final speed reducer of the mill drive to the mill’s top roller. The driving half is attached to the speed reducer’s output shaft, while the driven half connects to the mill top roller. Torque is transferred through Polyester Slings, offering flexibility and allowing the coupling to handle significant misalignments between the gear and roller.

This innovative design minimizes bending moments and eliminates the high thrust caused by axial and radial misalignments, providing a reliable, flexible, and efficient connection.

- Enhances the Mill’s extraction performance. The typical tail bar obstructs the mill top roller from freely floating. The Multi Misalignment coupling does not constrain the top roller. With the top roller free-floating, the mill operates at the planned setting and optimal hydraulic pressure, resulting in increased efficiency.

- If placed at the end of the milling process, the final bagasse moisture content will be lower.

- Misalignment between the square end of the gear shaft and the top roller, either as a result of the Top Roller tilting or as a result of an initial alignment issue in installations where the Sling Coupling is entirely absorbed. As a result, the final gear receives no considerable lateral force or bending moment.

- Mill torque and power usage are reduced.

- Crown pinion and top roller breakage are entirely eliminated.

- Negligible upkeep.

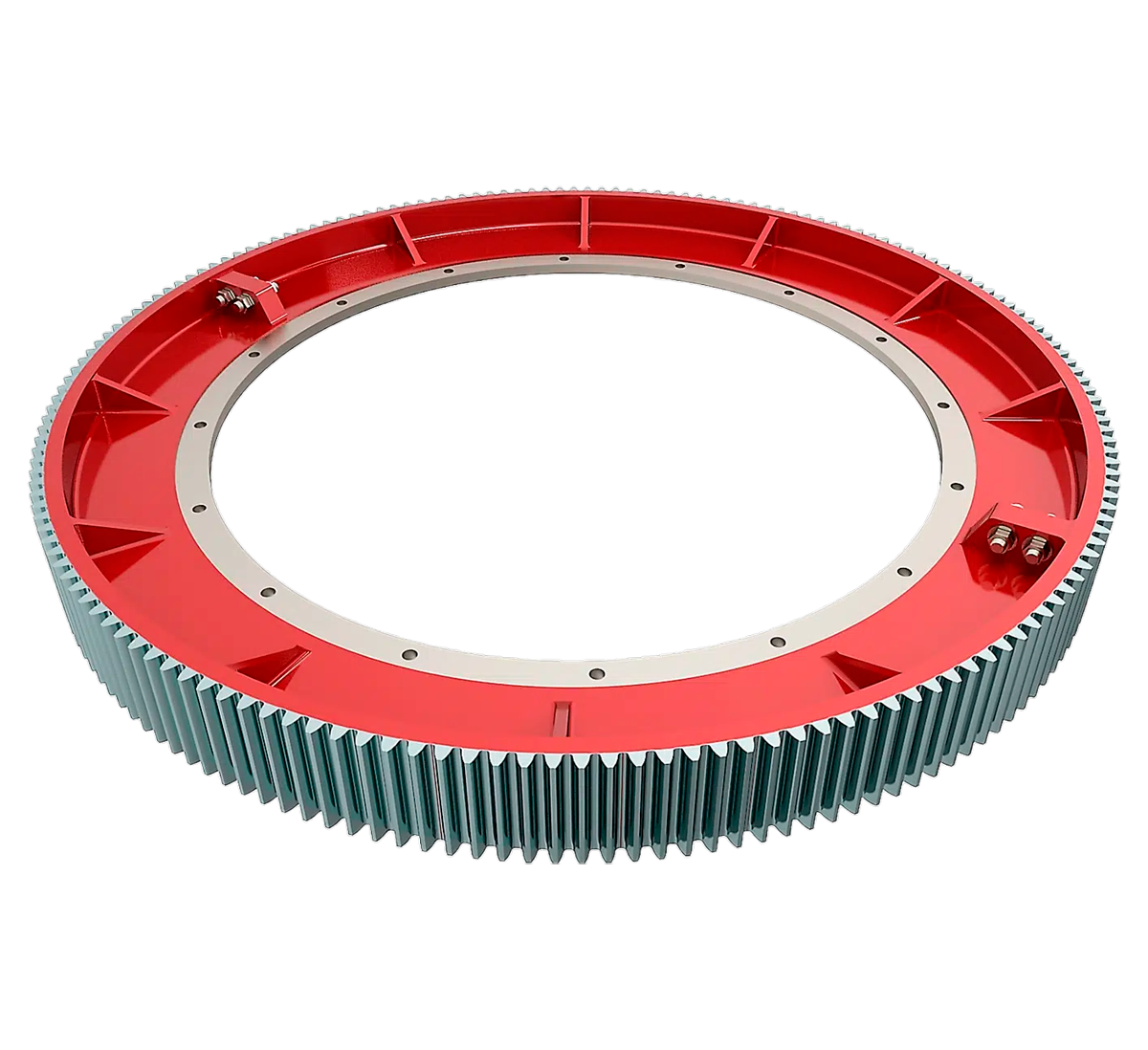

Sling Coupling Design

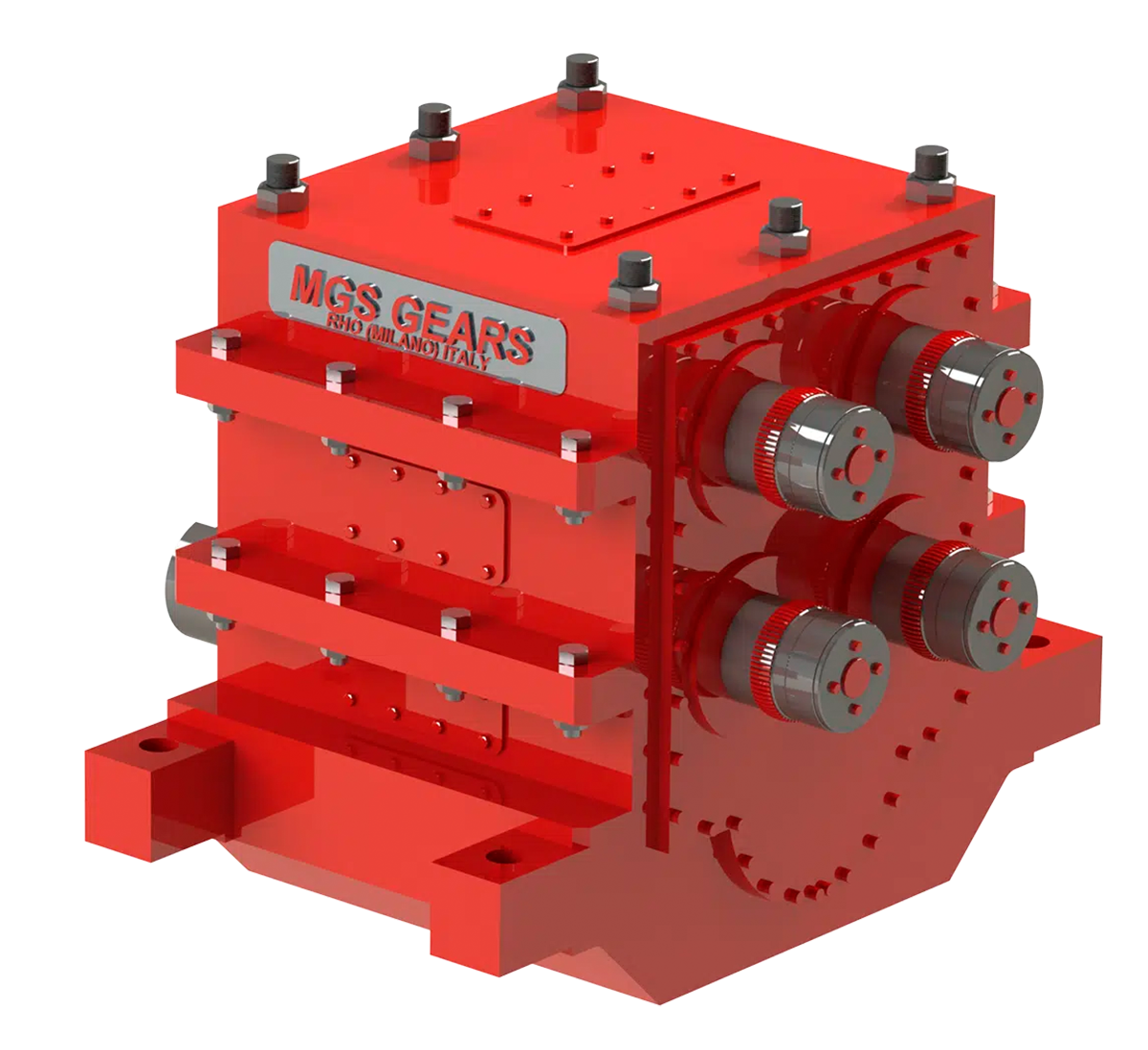

- Sugar Mills: Ideal for replacing traditional couplings in sugar mill top rollers, where reliable torque transmission and flexibility are essential.

- Cement and Steel Mills: Used in heavy-duty mills requiring efficient torque delivery and the ability to handle misalignments.

- Mining Operations: Applied in milling equipment where high torque and flexible coupling solutions are needed to accommodate misaligned shafts.

- Rotary Machinery: Suitable for machines with frequent misalignment issues, ensuring smooth and consistent power transfer.