Description

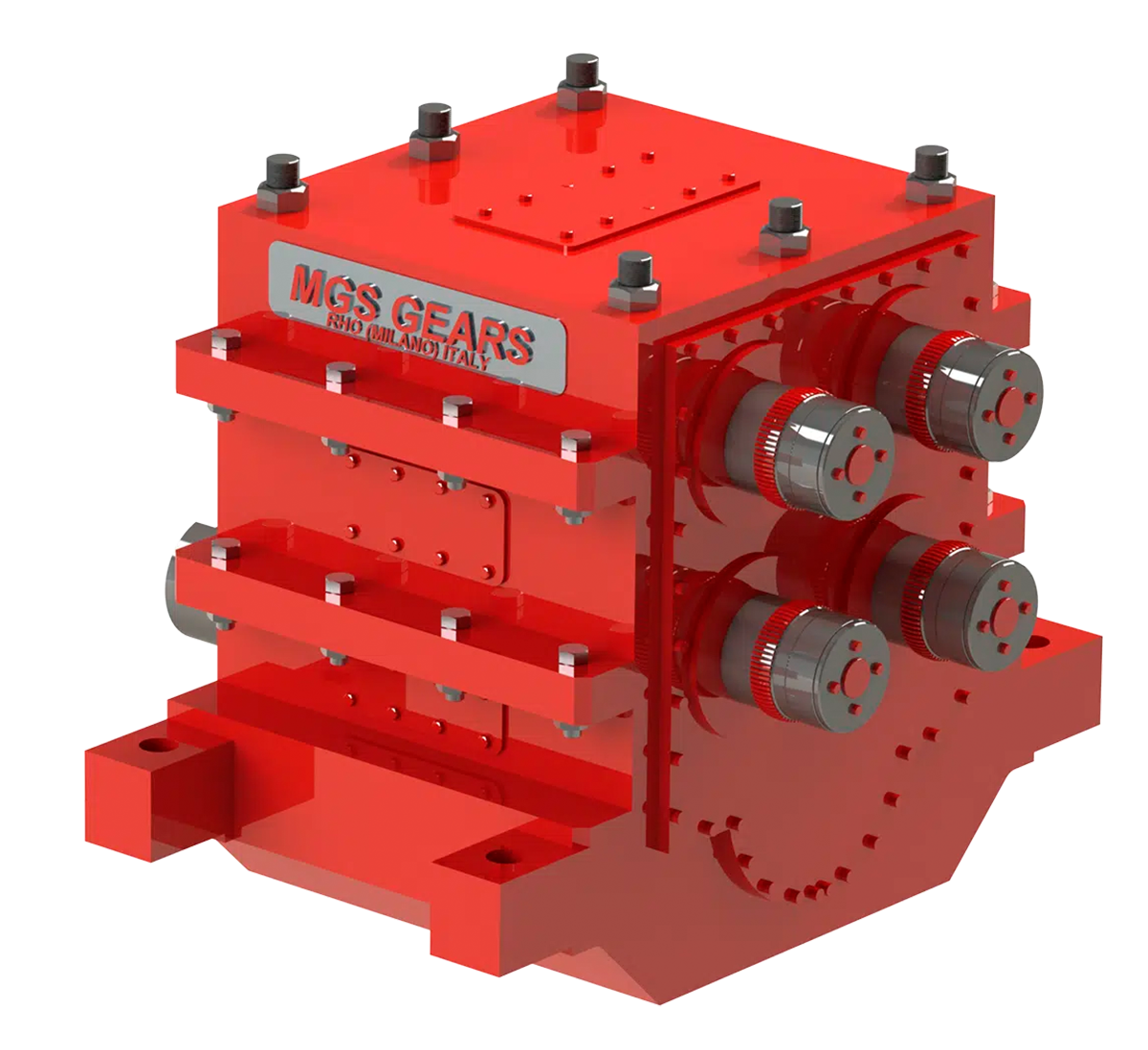

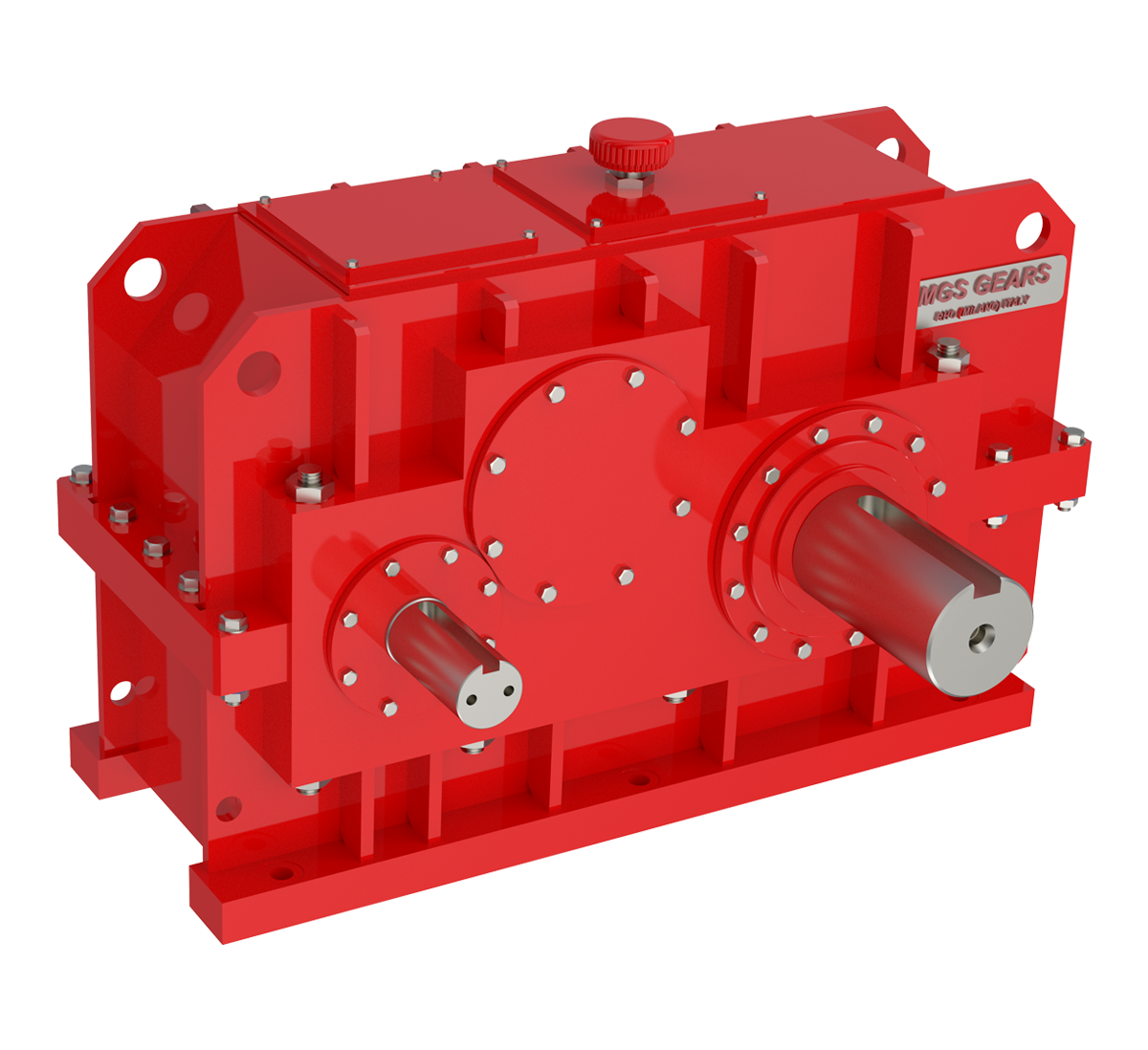

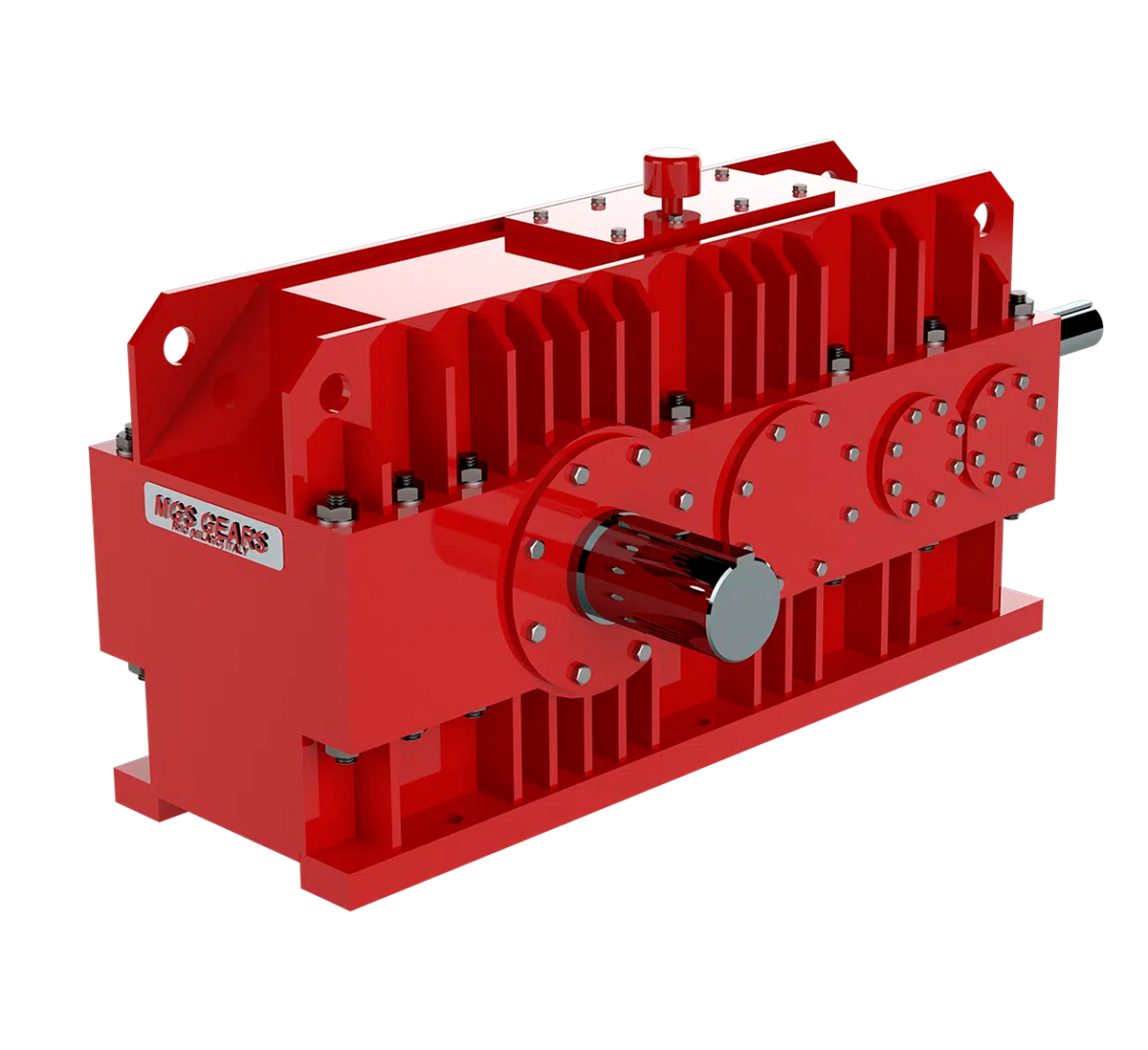

Custom-designed GEARMOTORS from MGS Gears integrate the latest technological innovations, incorporating advanced materials, specialized coatings, and high-performance bearings. These gearmotors feature optimized gear tooth designs, engineered to reduce noise, enhance strength, and extend service life. They deliver high torque at low power or low speeds, making them ideal for force-intensive applications.

As fully integrated units, gearmotors eliminate the need for couplings and minimize alignment issues, which can otherwise result in increased engineering time, costs, and potential bearing failures. Additionally, they can be paired with motors tailored to meet specific application requirements, providing a versatile and efficient solution for a wide range of industrial uses.

- Advanced Materials and Coatings: Incorporates cutting-edge materials and specialized coatings to enhance durability and resistance to wear.

- High Torque, Low Power: Provides exceptional torque even at low power or speed, ideal for applications requiring force and precision.

- Optimized Gear Tooth Design: Reduces noise and vibration while increasing overall strength and efficiency.

- Extended Service Life: Improved gear designs and bearings extend the lifespan of the gearmotors, reducing downtime and maintenance.

- Integrated Design: Eliminates the need for couplings and reduces potential alignment issues, leading to faster installation and lower engineering costs.

- Customizable: Gearmotors can be combined with motors according to specific application needs, providing flexibility across different industries.

- Low Maintenance: Built to require minimal maintenance, contributing to long-term operational efficiency.

- Mining: Used in conveyors, crushers, and material handling systems where high torque and reliability are essential.

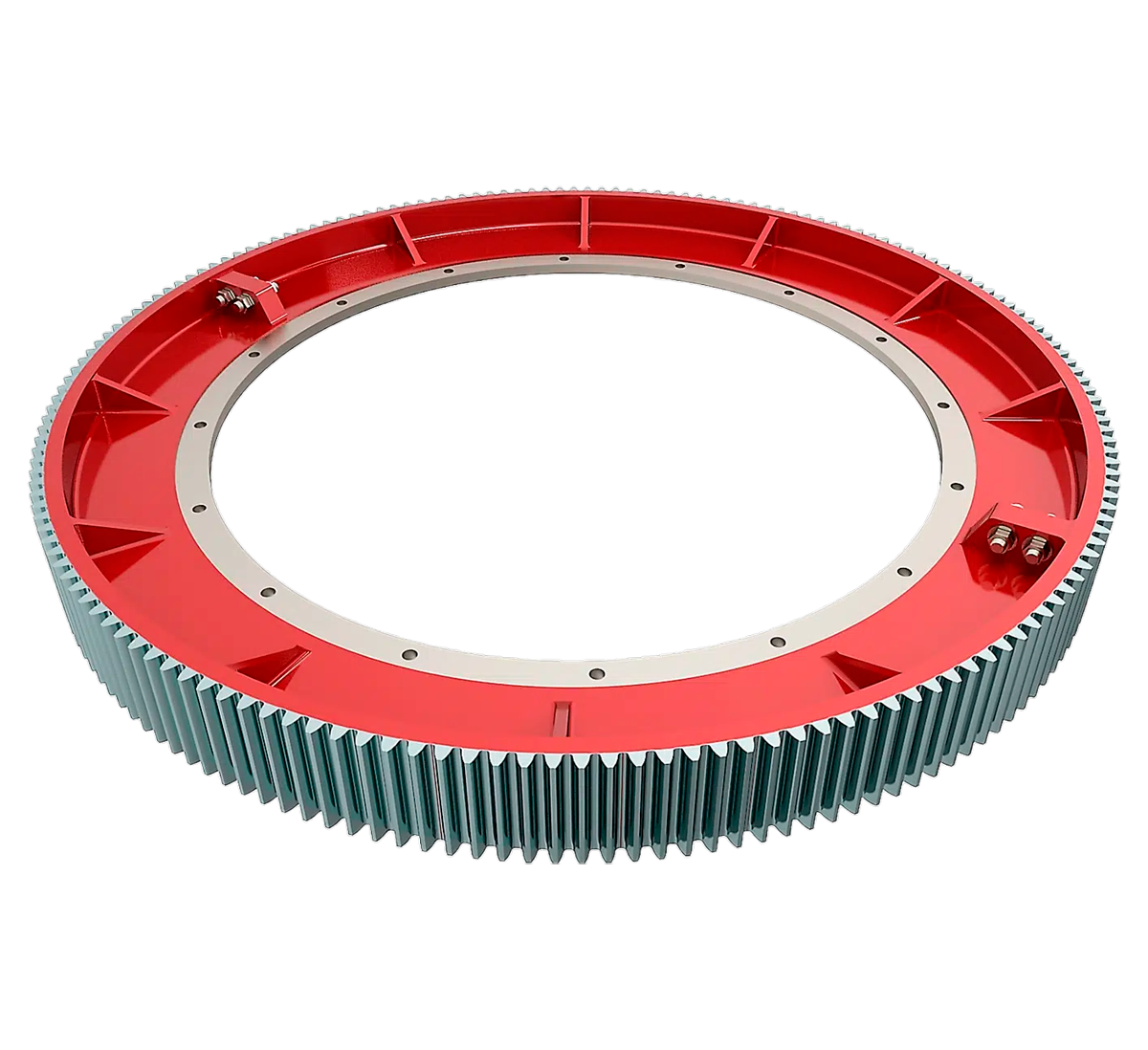

- Cement Plants: Ideal for heavy-duty equipment like kilns and mills, where high torque and precision control are required.

- Steel Industry: Applied in rolling mills, presses, and heavy machinery, ensuring smooth operation under demanding conditions.

- Sugar Industry: Employed in sugarcane crushers and centrifuges, offering durable and powerful torque transmission for efficient extraction and processing.

- Wind and Renewable Energy: Used in wind turbines and other renewable energy applications, providing reliable torque control for power generation systems.

- Automotive Industry: Integrated into assembly lines and testing equipment, where precise movement and torque are critical.

- Food and Beverage: Ideal for packaging and processing equipment that requires consistent, high-torque performance in hygiene-sensitive environments.